Wall-mounted CNC Router

Custom router for MIT Hobby Shop

In Spring 2021, our class, 2.77 - FUNdaMENTALS of Precision Product Design, came together virtually to design a wall-mounted router that would ultimately be manufactured and installed into a machine shop on MIT’s campus. The motivation behind the design was to create a route with a minimized footprint (the shop is packed full of other machines) but maximized board capacity (we needed to carve maple boards up to 9’x5.5’).

For the project, the class was broken up into three teams of seven. Each team was responsible to fully design- from early concepts to final drawings- an axis of the machine. I was assigned to the Y-axis and elected as the integration lead, who would interface with the other teams to ensure axes compatibility across the product. By the end of the project, the class had a fully design gantry-style CNC router ready to be manufactured!

Design Requirements

Can cut/carve 2” thick 9’ x 6’ hardwood

Extend < 3 feet from the wall

Can be manufactured by other machines in the shop

Key Responsibilities

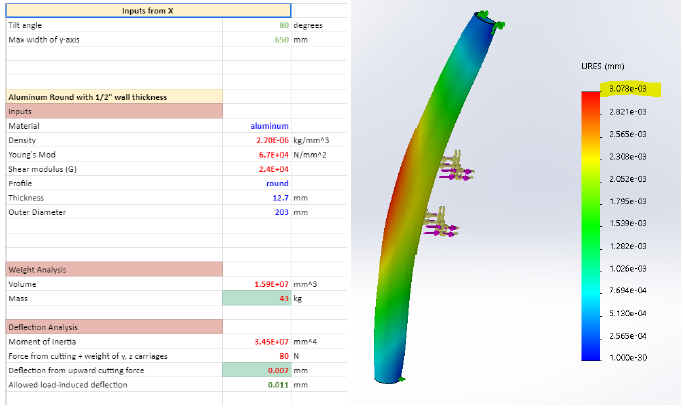

Designed the y-axis cross beam

Complete first-order beam bending analysis and FEA on beam to ensure

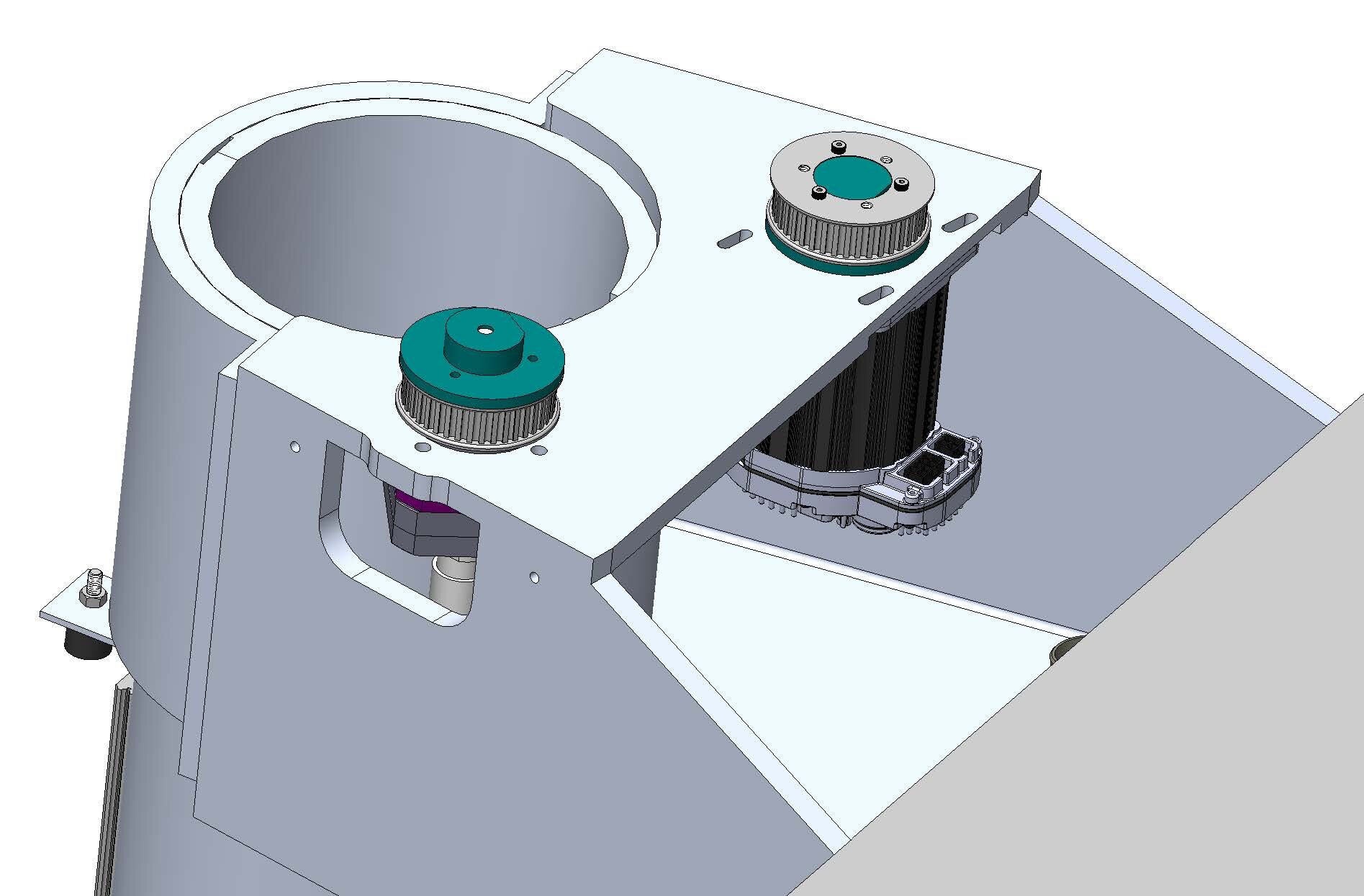

Designed Y-axis actuation system

Performed first-order calculations on the belt-driven system

Created Drawings for all parts designed (8 parts in total)

Homing Sensor integration

Integration Lead - the head person on the team to interface with other axes to ensure all designs were compatible

Master Assembly Person - sole person to bring all team’s CAD into one master file; utilized GradCad Workbench to ensure version control

Supported analysis and design efforts of other team members